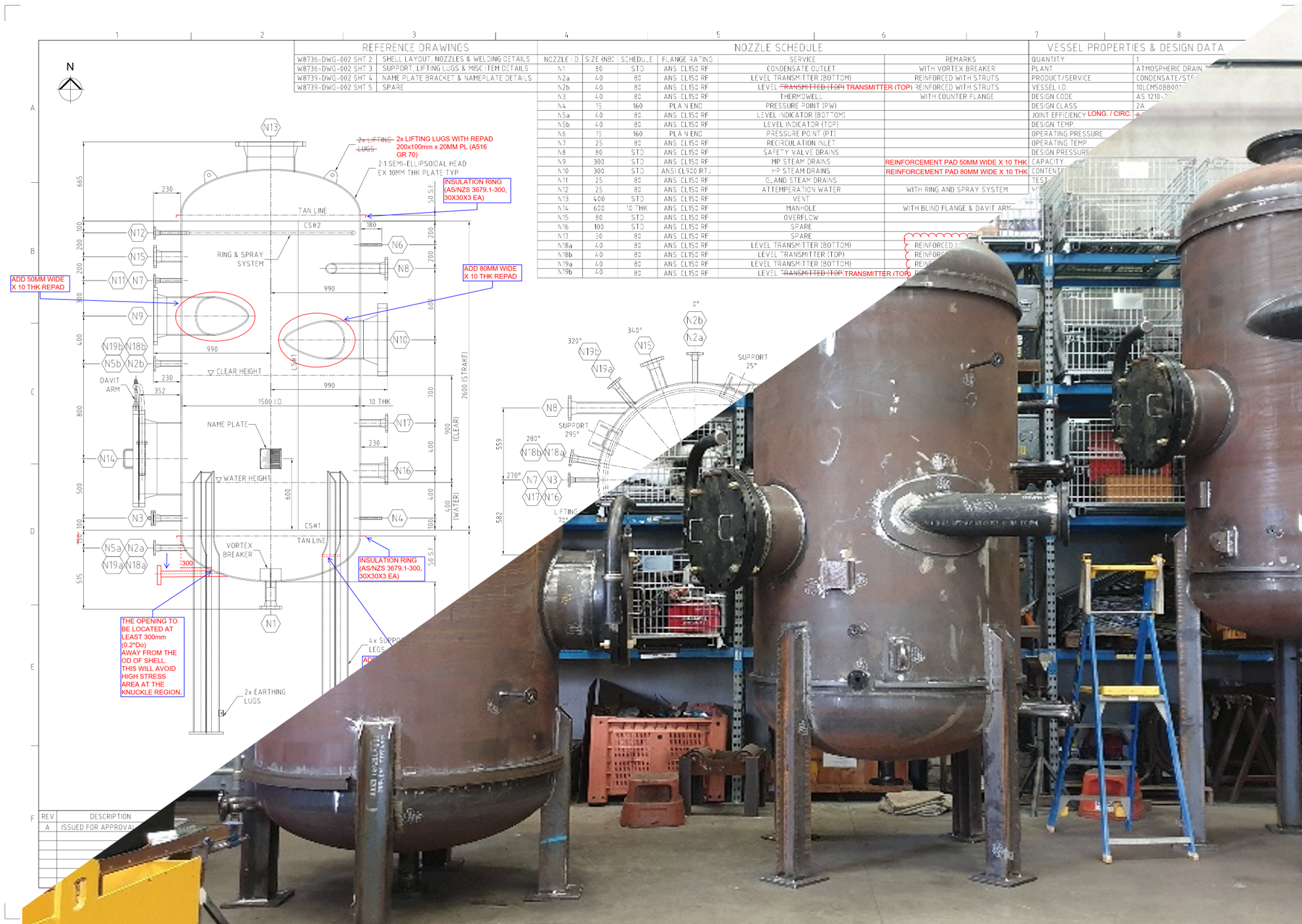

These designs were prepared in accordance with AS1210-2010 Pressure vessels.

Scope Of Work

- Design report

- Design verification certificates (3rd party)

- Signed designers and verifiers section of WorkSafe Application form 100

- Submission of application for design registration with WorkSafe WA.

Project Challenges

- Dispensation was required from the requirement to design for the loads calculated according to the project standards for nozzles larger than or equal to DN300 / NPS 12

- Resolution of design inputs to ensure vessels performed as expected by the plant owner

- Ongoing Basic Engineering design changes during Detail Engineering Development.

How We Managed This

Key element was review and mark up of the client’s drawings so they could release manufacturing drawings to their workshop that not only conformed to AS 1210 but also incorporated sound and standard manufacturing practice.

Value Engineering

Long standing professional relationship with our Client led to efficient use of the resources to reach the results that the Owner needed.