A Quality Assurance/ Quality Control engineer identified additional welding requirements, but they also required an Engineering Fitness-For-Purpose (FFP) assessment before release for service.

Scope Of Work

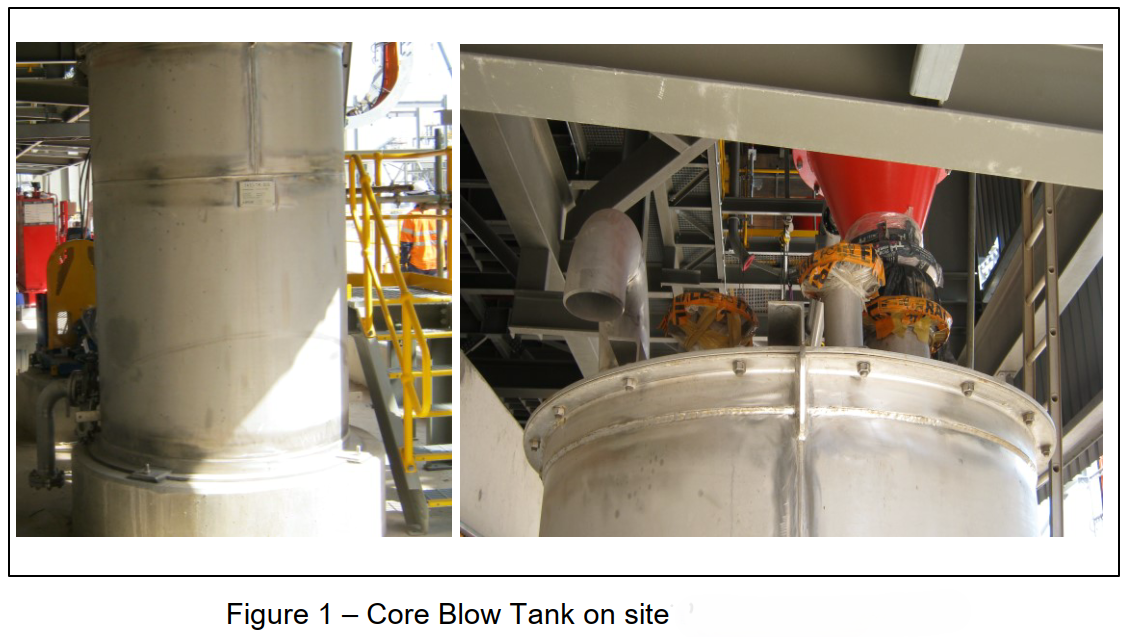

- Engineering assessment to assess the fitness for purpose of 2 atmospheric pressure storage tanks

- Gap analysis between the AS 3990 design and the API 650 requirements, and between AS 3990 design and API 620 requirements

- Report significant differences

- Assess whether the differences will have a material effect on safety or serviceability

- Make recommendations as to the acceptability of the AS 3990 design made.

Project Challenges

- The bottom cone welding details were not defined in the drawings. The typical tank details seemed to follow closely to API 650 requirement which does not allow for an unsupported bottom plate.

- According to API 620, each tank shall be provided with at least two manholes for inspection and repair. Manholes shall be greater than or equal to DN 500 along the inside dimension. There is only one inspection opening located on the roof and it was sized smaller than DN 500.

How We Managed This

In the absence of Visual Examination (VE) report in the Manufacturer’s Data Record, the VE was completed by Anergy Pty Ltd prior to final release and was shown in the inspection release certificate. The VE result indicated poor welding on the cone section of the tank. It was recommended to perform additional visual inspection on the cone section of the tank to make sure that none of the surface imperfections exceeded the allowable limit.